Anodizing Process Computer

- Automatic survey of the surface to be anodized

- Presetting of anodizing current density and requested number of microns

- Automatic printout of anodizing parameters

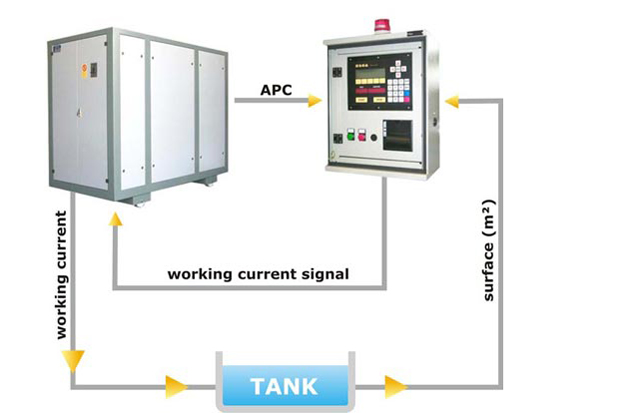

The APC (anodizing process computer) can calculate automatically, after a simple initial calibration, the value of the surface. (This one seen as electrochemical equivalent surface, that can be different from the one calculated geometrically due to the effect of screened parts). On the base of this value, and considering the set current density (A/dm2) the APC controls the total current supplied by the rectifier without any further manual adjustment for small or big loads.

The operator sets, on the keyboard, the requested current density and the requested number of microns.

After the start, the APC calculates the surface of the load and it sets the value of the total “Working current” fed to tank.

During the process some essential data are shown on the display of the APC.

The Cycle end alarm is operated when the number of microns obtained matches the pre-set value.

After the Stop button is pressed the APC prints automatically all anodizing process parameters.