for modern Aluminium colouring:

- Three phase supply

- Full solid state control (no moving parts)

- DC / AC output mode

- Programmable AC waveform (also not symmetrical output available)

- Computerized full digital control

2.000A – 4.000A

6.000A – 8.000A

10.000A – 12.000A

15.000A – 18.000A

20.000A – 25.000A

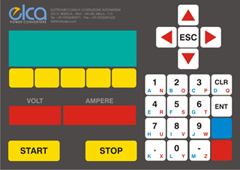

The operator can control the power supply directly, setting the type of output phase , the duration and the output voltage value by means of the keyboard.

Automatic working:After the waiting time the colouring process is carried out according to the program selected in the ELCA RAMPER.

A pre-alarm signal is available 1 min. before the end of the cycle.

After the cycle end the unit remains in “PARTIAL STOP” condition.

At this moment it is possible to operate according to the following 2 working ways:

START AGAIN: the unit supplies the same output a.c. voltage as before the partial

stop. When the preset time is expired, the lamp and the buzzer operate again

TOTAL STOP: by means of the proper button. It resets the unit.

RAMP TIME: (the same for both DC and AC phase): adjustable between 20÷50 sec.

Computerized control:

The power supply is provided with a proper process computer to allow the necessary system flexibility and the correct management of all the working parameters (phase type, output voltage, ramp times, …)

This computer can memorize up to 100 different programs and it takes care of the automatic execution of programmed cycle. Provided with printer on request.