- Constant current or constant voltage control

- Process duration

- The output polarity

- The output value

- Up to 100 different programs can be created and saved by the user.

- Each program allows the programming of:

- Constant current with voltage limit or Constant voltage control;

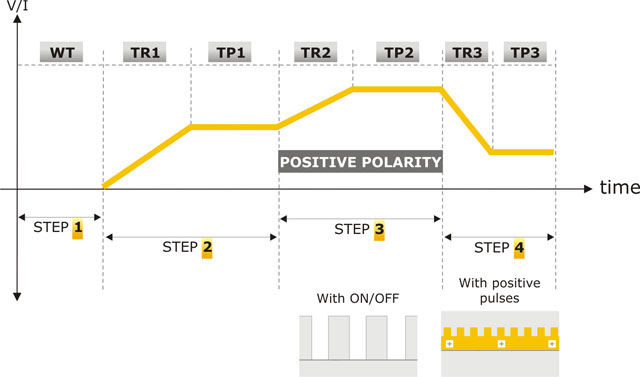

- Up to 20 ramps and dwell times (Steps);

- Working ways (with or without pulses, with independent parameters

for each step); - Duration of the process based on the Time or on the Ampere-hours number.

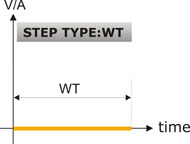

- WT (time without any output)

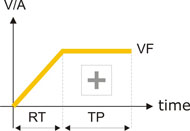

- POS (positive polarity output). In the POS step also the working way can be set

Available type of steps:

Parameters:

- - Dwell time - WT

Parameters that can be set in the POS step:

- Ramp time - TR

- Dwell time - TP

- Final Value - VF

- Base Time

- Pulse time

- Pulse Amplitude