Process Computer ELCA RAMPER

ELCA digital rectifiers are provided with a powerful digital controller that takes care of all control functions and allows automatic working.

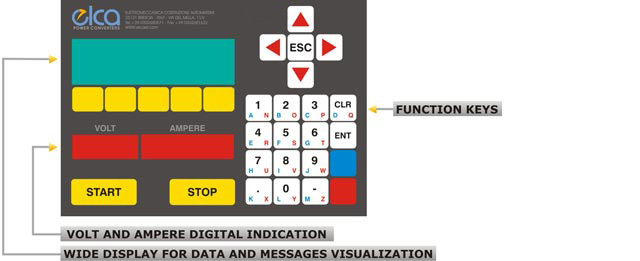

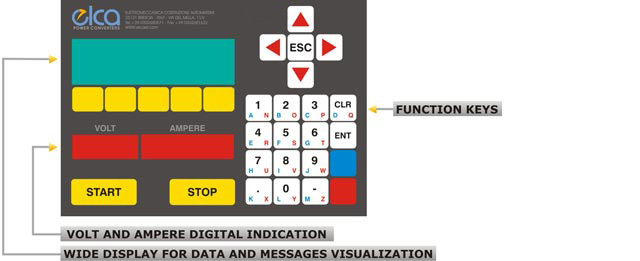

The operator panel is provided with:

The operator can always operate the unit in manual mode, setting:

- Constant current or constant voltage control

- Process duration

- The output polarity (types NR and PRPR only)

- The output value

Moreover the full automatic execution of the working cycles is possible:

- Up to 100 different programs, each one consisting of several steps, can be created and saved by the user.

- Easy programming by means of simple command menus. (different languages available)

- Data retention without supply and without back-up batteries.

- Serial port (RS485) for digital communication (standard Modbus Protocol)

- Alarm messages visualization

- Printer for the printout of the process parameters on request (Optional)

See other Ramper details:

type N ;

type NR ; type PRP ;

type PRPR