Process Computer ELCA RAMPER type NR

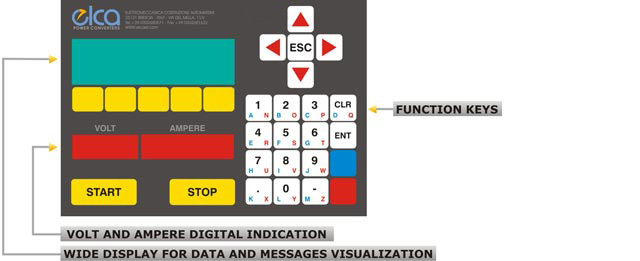

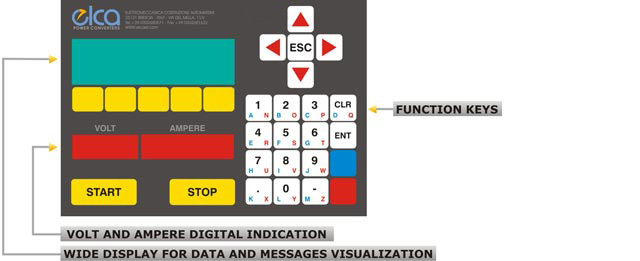

The process Computer ELCA RAMPER is a powerful digital controller that takes care of all control functions and allows automatic working.

The operator panel is provided with:

The operator can operate the unit in manual mode, setting:

- Constant current or constant voltage control

- Process duration

- The output polarity

- The output value

Moreover Full automatic execution of the working cycles is possible:

- Up to 100 different programs can be created and saved by the user.

- Each program allows the programming of:

- Up to 20 ramps and dwell times (Steps);

- Duration of the process based on the Time or on the Ampere-hours number.

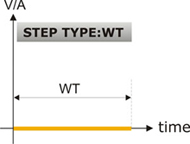

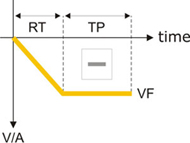

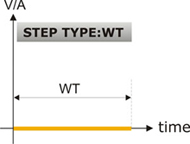

The type of each Step can be chosen among the three following:

- WT (time without any output)

- NEG (negative polarity output)

- POS (positive polarity output)

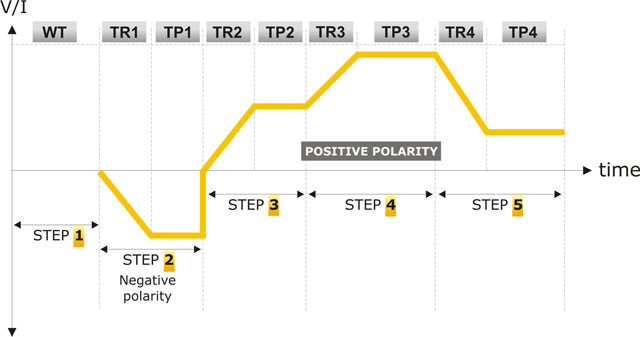

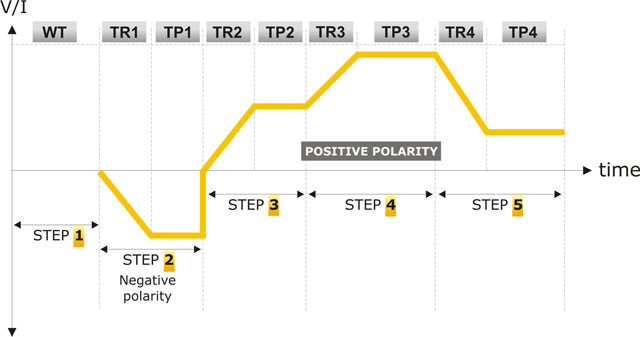

STEP description and program example

Available type of steps:

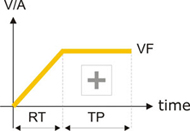

Parameters

Parameters that can be set in the NEG Step:

- Ramp time - TR

- Dwell time - TP

- Final Value - VF

Parameters that can be set in the POS step:

- Ramp time - TR

- Dwell time - TP

- Final Value - VF

The proper step sequence allows to create any type of program as the following in the example: